Let's describe the production of cat litter as a business. To do this, you just need to purchase simple equipment and master simple technology. Experts estimate the profitability of such a project to be quite high, but much depends on competition in a particular region.

For cat lovers, it is important that stores have a sufficient selection of such products. After all, litter for toilets is purchased almost as often as food. It performs the function of absorbing liquids, eliminating unpleasant odors and must be safe for animal health. If you offer customers a high-quality and inexpensive product, then there will be constant demand for it.

Business benefits

Creating such a project is profitable because:

- Organic filler is very cheap and available to almost all customers.

- The raw materials for its production are easy to find, and the cost of production is quite low.

- Relatively small starting capital is required.

- Profitability is estimated at 100-150%, which looks very attractive.

- No special knowledge or training in production is required.

- When opening a company and completing paperwork, no additional product certification is required, and regulatory authorities rarely inspect such a workshop.

- You can simultaneously produce other goods from the same raw materials, which will significantly expand the range and increase profits.

Production technology

The production of cat litter itself includes the following technological steps:

- Preliminary drying of raw materials, which is then sent for crushing.

- Additional drying. At the exit, the raw material should have a moisture content of no more than 8-12%.

- Subsequent crushing of chips using a hammer crusher.

- Moistening the resulting raw material with steam (for its subsequent better gluing).

- Pressing into molds and cooling of granules.

- Sifting and packaging of finished products. By the way, bags for fillers can also be produced independently, since the cost of this process is low.

Types of fillers

Depending on what it is made from, the following options are distinguished:

- Organic - their composition has a natural basis. The materials used can be corn waste, wood shavings, pellets, nut shells, etc. They are considered the cheapest and easiest to produce, and the only disadvantage is the possibility of individual particles sticking to the paws of the animal.

- From bentonite clay or zeolite minerals, a clumping substance is obtained, which, when wet, easily collects into a separate piece and is simply removed with a spatula. But to use it, it is better to purchase a tray with high sides so that the filler does not spill on the floor.

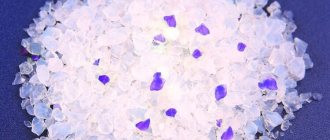

- Silica gels are high-quality products that provide good absorbency. But some cat owners have noticed that not all animals like the special rustling sound from the touch of their paws with such a filler.

The simplest and most affordable option is to purchase an automated line for the production of organic goods, for example, from sawdust. The remaining equipment, as well as the raw materials themselves, will cost much more, which will require serious expenses.

Wood pellets, which are waste from wood processing, are used as a base. Therefore, it is beneficial to establish constant contact with such organizations and receive from them ready-made raw materials measuring 6-8 mm. Their recycling will be simple and quick.

In addition to cat litter, similar products can be produced from the same material. Thus, without special costs, it is possible to expand the range of products and produce fuel for fireplaces, barbecues, fertilizer for the soil, bedding for cattle, etc.

The best raw materials

If you are just starting to expand your production, then it is best to use ready-made wood pellets. Their diameter is approximately 6-8 mm. They are usually produced in large quantities at wood processing enterprises, and pine and spruce wood is most often used as raw material.

The fact is that this particular material not only actively absorbs biological fluids, but also has a bacteriostatic and bactericidal effect. Among all the wood fillers for cat litter, spruce is the most practical solution. Since the raw materials are cheap, sales of such fillers are growing every year.

Premises and transport

Finding a suitable building for setting up a workshop is quite easy. To save money, rent a small area on the outskirts of the city or even outside it. Dimensions may not exceed 50 square meters. m. It needs to be divided into a work area and a storage area. Conveniently, the finished filler does not require special storage conditions.

Don't forget to take care of transportation. It is most convenient to deliver raw materials and deliver goods to stores when you have your own truck. If you do not have sufficient finances, you can initially do this using a rented car.

Equipment

A full-fledged automated line consists of the following elements:

- chopper;

- Dryer;

- granulator;

- cooler;

- packaging machine.

You can purchase equipment either as a ready-made kit or separately. To save money, use used equipment or find inexpensive lines from a domestic manufacturer.

Experienced entrepreneurs advise paying special attention to granulators. They provide a convenient granular form to the material. This equipment can be bulky and occupy almost the entire workshop, or it can be compact in size. The second option can be installed immediately at a woodworking enterprise and receive finished goods.

Technological process

Let us briefly describe how the creation of an organic filler occurs:

- Pre-dry granules, shavings, sawdust or other raw materials.

- Then additional drying is carried out to achieve a moisture level of the material not exceeding 10%.

- The raw materials are crushed using a hammer crusher.

- Steam is passed through it to moisten it, causing the substance to stick together.

- Next you need to process it with a press.

- Cool the products.

- Sift and pack into containers of 5, 10, 15 and 30 kg.

Typically, simple Zip Lock bags are purchased for packaging and a label with the company logo is printed separately.

Purchase and installation of equipment

To organize the production of organic filler, you will need to purchase a basic automated line OGM-1/5. This device, worth 2 million rubles, is designed to work in difficult conditions.

This opportunity is realized thanks to a modernized press unit, a new dispenser, shafts and gears made of stainless steel. When purchasing equipment to create a production line, you will need to separately purchase:

- chip grinder – 180 thousand rubles;

- granulator – 50-500 thousand rubles;

- dryer - 400 thousand rubles;

- rental of premises - 20 thousand rubles.

- pellet cooler – 400 thousand rubles.

Initial investment of 1.5 million rubles. will pay off quickly. For packaging, bags designed for volumes of 5, 10, 15 and 30 liters are recommended. You can save on the cost item for purchasing packaging production equipment by using an alternative option. To do this, you can purchase simple bags, the cost of which is a few rubles per piece. and stick on them the labels ordered from the printing company.

The granulator should play an important role in the technological process. The quality and cost of the final product depends on its performance and technical parameters. Complex equipment lines use bulky models that take up a lot of space.

In order to optimize and rationally use the usable area of the workshop, you can install compact production equipment. This will allow you to place other equipment at a woodworking enterprise or furniture workshop, and thanks to this, receive additional types of goods.

Staff

Is it necessary to hire employees for such production? If you are focusing on large volumes of manufactured goods, then it is advisable to hire 2 people. Since no special skills or knowledge are required here, it is enough to find unqualified specialists and pay the minimum wage.

Separately decide whether you need an accountant and a sales manager. Typically, such functions are performed by the entrepreneur himself. But if you don’t have enough necessary knowledge, you can hire such personnel separately. Accounting is often outsourced, which significantly reduces labor costs.

Rules for using wood filler

In order for the filler to fully cope with its functions, it should be used correctly:

- Pour the granules into a dry tray in a layer of 2–3 cm, after which they need to be evenly distributed.

- If the filler is clumping, then only the formed lumps can be removed, and everything else can be used further.

- All contents change as they become dirty, but it is recommended to do this at least once a week.

- Before the next filling, the tray must be washed, disinfected and dried.

- The filler can be disposed of in household waste containers or washed in small portions down the drain.

Advertising and sales

Deciding on what types of fillers there are, choosing your niche and producing the first batches of goods is only half the battle. The profitability of a business is directly affected by its implementation. You can set up the sale of cat litter through the following channels:

- pet stores;

- large shopping centers;

- Internet;

- wholesale centers;

- nurseries.

To stand out among competitors and convey information to the end consumer, you can organize an advertising campaign on local television by creating a short video. Thanks to this, customers will begin to recognize the brand by its logo and name and will want to try the new product. But if you want your product to be purchased on an ongoing basis, then produce only high-quality products.

Production process of cat litter for litter box

Your kitten spends a lot of time digging through the litter in her litter box, and you, as a caring owner, have to spend just as much time collecting it. But what do you know about what you put in your cat's litter? Perhaps now is the time to stop and ask, “How is cat litter made?”

There are three main types of fillers on the market: mineral, silica gel and plant-based. Knowing how each is made will help you decide which one is best for you and your kitten.

From this article you will learn about fillers from composition to manufacturing process.

The production of cat litter, as a business idea, can be carried out if you have the necessary equipment, and you have mastered simple cultivation technology. This kind of idea is popular these days, and experts consider it very broadly, but in most cases the success of the project will depend on competitive conditions in a particular region.

Tips for beginners

To avoid spending too much money at the start and quickly achieve full payback, you can try the following:

- Find a permanent supplier of raw materials closer to your workshop. So, delivery will be cheaper.

- By working in several shifts and maximizing the range of products produced, you can achieve high profits.

- Try to sell fillers not only through large chains and stores, but also find access directly to consumers.

- By purchasing used equipment, you will significantly reduce costs and only purchase newer ones over time.

Mineral filler

This filler was invented in 1940. Since then it has become popular, with many consumers choosing this type to fill their cats' litter boxes. Its composition is indicated by its name - this filler is made from clay mineral rocks, known for their softness and absorbent properties.

The material for production is mined in large quarries, then transported to production plants, where the raw materials are crushed, then loaded into a kiln, and then crushed again.

The crushed material is passed through several sieves to sort the fractions by size. The ability to absorb liquid will be lower if the filler is made from fractions of only one size. To obtain a material with high absorbent properties, different sizes are mixed.

At the last stage, bentonite is added to the material to increase pelletizing properties. It can be dangerous because when moistened, its volume increases 15 times. Eating pellets containing bentonite can cause an obstruction in the kitten's digestive tract.

Substances are also added to the composition to reduce dust formation when moving material. Fillers often contain odor neutralizers, such as baking soda. These substances eliminate unpleasant odors, such as the smell of the cat's litter box.

Some cat owners may have problems with mineral litter. It is easily carried on the paws; dust containing particles of this litter can cause lung problems in your cat. In some cases, mineral mining can harm the Earth. Additionally, used litter ends up in landfills after you throw it away.

Financial part

We will provide average figures, although depending on the chosen model of equipment, the final calculations will vary greatly.

| Start-up investments | Cost, in rub. | |

| 1 | Chopper | 180 000 |

| 2 | Dryer | 400 000 |

| 3 | Granulator | 500 000 |

| 4 | Cooler | 400 000 |

| 5 | Workshop rental | 20 000 |

| Total: | 1 500 000 |

Raw materials for organic filler cost no more than 4 rubles per kg. You can sell finished goods for 100-200 rubles. This way, your initial investment will pay off fairly quickly. Profitability is estimated at 100-150% and within six months you can receive a net profit from production.

Video: how is cat litter made?

Feasibility of the idea

The production of cat litter involves the use of various substances. The production of gel and clumping materials involves the use of expensive raw materials, so organizing such a business is economically profitable in large cities.

Bentonite clays are an excellent raw material for production. Enterprises that produce products on an industrial scale have:

- internal communications;

- equipment;

- technology;

- infrastructure for organizing supplies to remote regions.

The filler production process includes:

- supplying clay with a grab crane to the line hopper;

- drying;

- splitting up;

- fractionation of granules by class;

- packaging;

- storage of finished products;

- shipment to customers.

Bentonite clay is a mineral that has the ability to absorb moisture. Industrial enterprises are constantly improving production technology, using a complex of active substances that enhance adsorption properties.

Silica gel products are made from synthetic crystals, but some cats refuse to use them due to the rustling sound and sharp edges of the components. The production of filler as a business is considered when using other (organic) materials:

- nut shells;

- peat;

- sawdust;

- straw;

- sunflower husks;

- corn waste;

- wood shavings.

The advantage of using fillers made from these environmentally friendly materials is low cost and ease of disposal. The production of cat litter from sawdust can be organized as an additional activity for enterprises producing fuel pellets.

Natural materials perfectly absorb moisture, neutralize odors, and are safe for animals, so the product does not require certification. Implementing a manufacturing project has benefits that include:

- low cost and selling price of products;

- easy to purchase raw materials for manufacturing;

- business requires small investments;

- the profitability of the idea is estimated at 100-150%;

- simplicity of organizing the process.

The production of fillers from sawdust is an excellent area for small business development.

Reviews

Sergey: “Organic fillers are more profitable, since it is easy to find buyers for them, because they are cheap. And today there is competition mainly only among expensive companies that use artificial raw materials.”

Dmitry: “I installed such a line and constantly produce volumes of goods in sufficient quantities to cover the needs of the region. The profit is enough for a comfortable life, but there is no point in expanding, since delivery to other regions will significantly increase the cost of the goods.”

Olga: “First you need to study the market well and analyze the wishes of customers, the main demand. For example, I discovered that our cat owners only buy proven, albeit expensive, brands. They don’t pay any attention to any new products, even organic and cheap ones. I had to sell the line and do something else.”

Silica gel filler

Silica gel's ability to absorb may seem like a miracle of modern science. To make these amazing little beads, sodium silicate (a synthetic form of silicon dioxide - also known as sand) is mixed with water and oxygen.

When sodium silicate, water and oxygen combine, they form beads with tiny pores that give them incredible absorbency. Silica gel absorbs liquid and traps unpleasant odors, these are excellent qualities for cat litter.

Fresh Cat Silica Gel Litter uses advanced technology in the production of cat care products.

Fresh Cat Litters are manufactured in one of the largest and most trusted manufacturing facilities in the world, using carefully selected raw materials and the highest quality control standards.

It's also virtually dust-free, which is good news for asthma-prone cats, since veterinarians generally don't recommend even the lowest-dust mineral litters for cats with asthma, nor do they for those who have just had surgery.